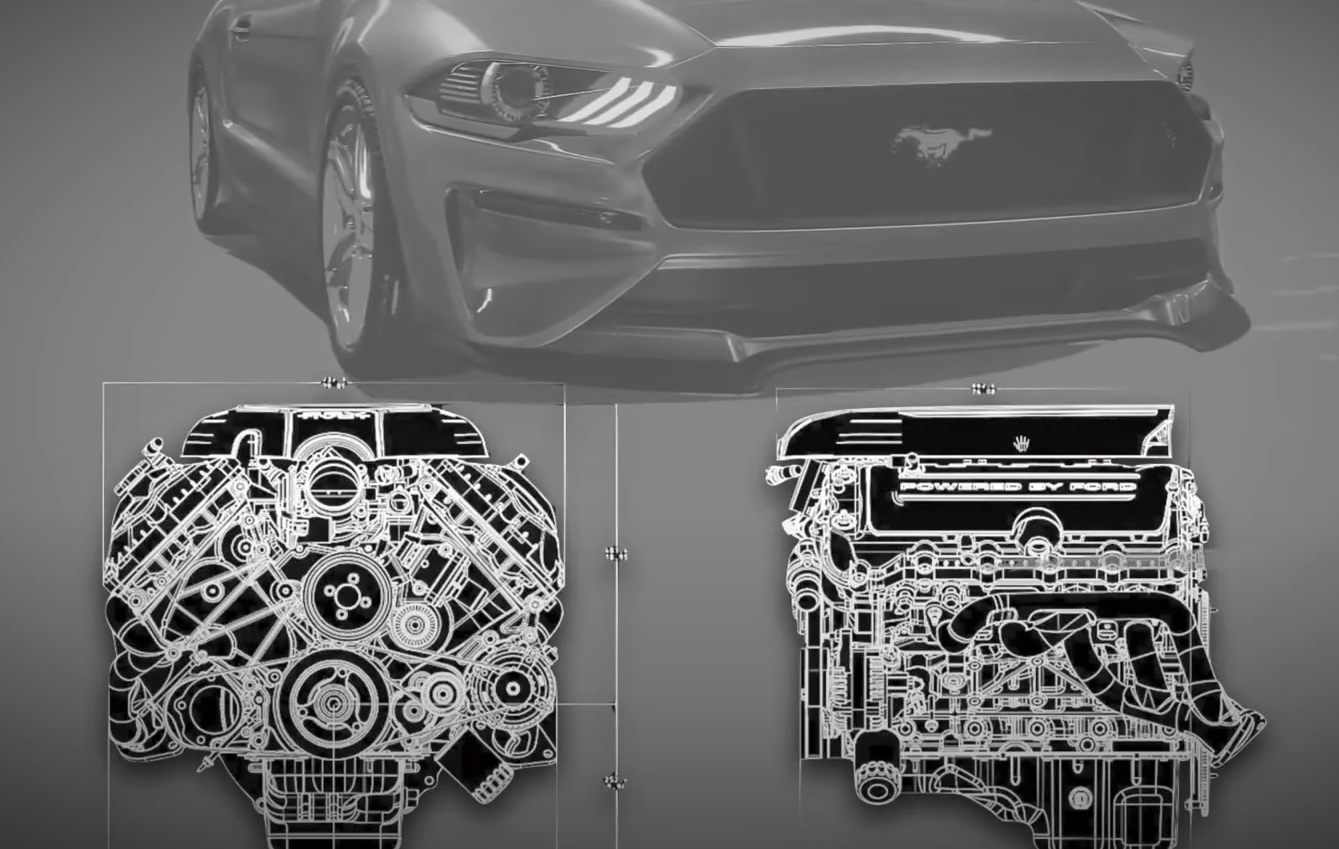

The Ford 5.0L V8 Coyote engine has become a defining powerplant in modern performance and utility vehicles. Introduced in 2011, it was developed to replace older modular V8s while competing with rival engines from GM and Chrysler. Built with a focus on efficiency, strength, and adaptability, the Coyote quickly established itself as a reliable option for both daily driving and high-performance use in models like the Mustang GT and F-150.

Its design combines lightweight materials with durable components, advanced fuel systems, and precise valve timing to deliver strong horsepower and torque across different applications. Over the years, updates have improved output and technology, though newer versions also bring added complexity and maintenance considerations. Even with these trade-offs, the Coyote remains a respected choice for those who value naturally aspirated V8 performance with modern engineering.

Key Takeaways

- The engine was created to balance power, efficiency, and adaptability

- Design updates improved performance but added complexity

- It remains a strong and reliable option for both daily use and performance needs

Coyote Engine Overview

Launch and Engineering Origins

The 5.0L Coyote V8 entered production in 2011 as a fresh design to replace Ford’s older 4.6L and 5.4L modular V8s. Engineers built it to compete with GM’s 6.2L V8 and Chrysler’s 6.4L Hemi while still running on regular 87-octane fuel.

Key design choices included:

- Aluminum block with cast iron liners (Gen 1 and Gen 2) and plasma arc spray liners (Gen 3)

- Forged steel crankshaft and powdered metal connecting rods for strength

- DOHC setup with four valves per cylinder

- Twin independent variable camshaft timing (Ti-VCT) for precise intake and exhaust control

Fuel delivery evolved from sequential multiport injection (2011–2017) to a dual system in Gen 3, combining port and direct injection for better efficiency and reduced carbon buildup.

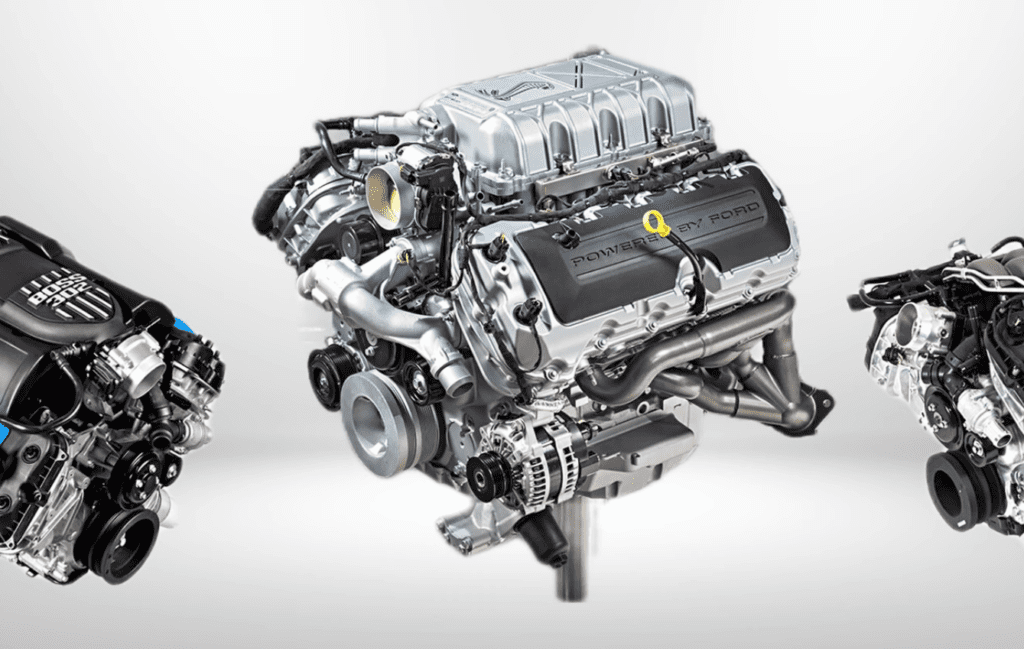

Use Across Ford Vehicles

The Coyote powers several Ford models with tuning differences based on application:

| Model | Years | Output Highlights | Notes |

|---|---|---|---|

| Mustang GT | 2011–2017 | Up to 435 hp | High-rev focus |

| Mustang GT (Gen 3) | 2018+ | 460 hp, 7,500 rpm redline | Dual injection system |

| F-150 | 2011–present | Torque-focused tuning | Cast exhaust manifolds, towing durability |

| Falcon GT / XR8 (Australia) | Limited years | Performance variant | Export use |

| TVR Griffith | Later model | Adapted version | Sports car application |

Mustang versions feature tubular stainless steel headers for improved exhaust flow, while the F-150 prioritizes durability with cast manifolds.

Market Position and Rivals

Ford positioned the Coyote as a naturally aspirated alternative to larger-displacement rivals. Compared to GM’s 6.2L V8 and Chrysler’s 6.4L Hemi, the Coyote offered:

- Smaller displacement with competitive horsepower

- High-revving character uncommon in domestic V8s

- Balance of power and efficiency while maintaining reliability

Although turbocharged EcoBoost engines surpass it in fuel economy, the Coyote remains valued for its traditional V8 feel, instant throttle response, and long-term durability in earlier generations.

Technical Specifications

Engine Design

The 5.0L V8 uses an aluminum block with either cast iron liners in early versions or plasma arc spray cylinder walls in later models. A deep-skirt block supports four-bolt main bearing caps, while a forged steel crankshaft and powdered metal connecting rods handle both high RPM and daily use.

The DOHC setup includes four valves per cylinder. Timing relies on chains for each camshaft, and actuation uses roller finger followers with hydraulic lash adjusters. The system features twin independent variable cam timing (Ti-VCT), which adjusts intake and exhaust cams separately.

Structure and Components

Key parts include:

- Piston cooling jets for heat control

- Plastic intake manifold with variable runner control

- Tubular stainless steel headers on Mustang models

- Cast exhaust manifolds on F-150 models for durability

| Component | Material/Design |

|---|---|

| Block | Aluminum |

| Cylinder liners | Cast iron (Gen 1–2), Plasma arc spray (Gen 3) |

| Crankshaft | Forged steel |

| Connecting rods | Powdered metal |

| Valve train | DOHC, 4 valves per cylinder |

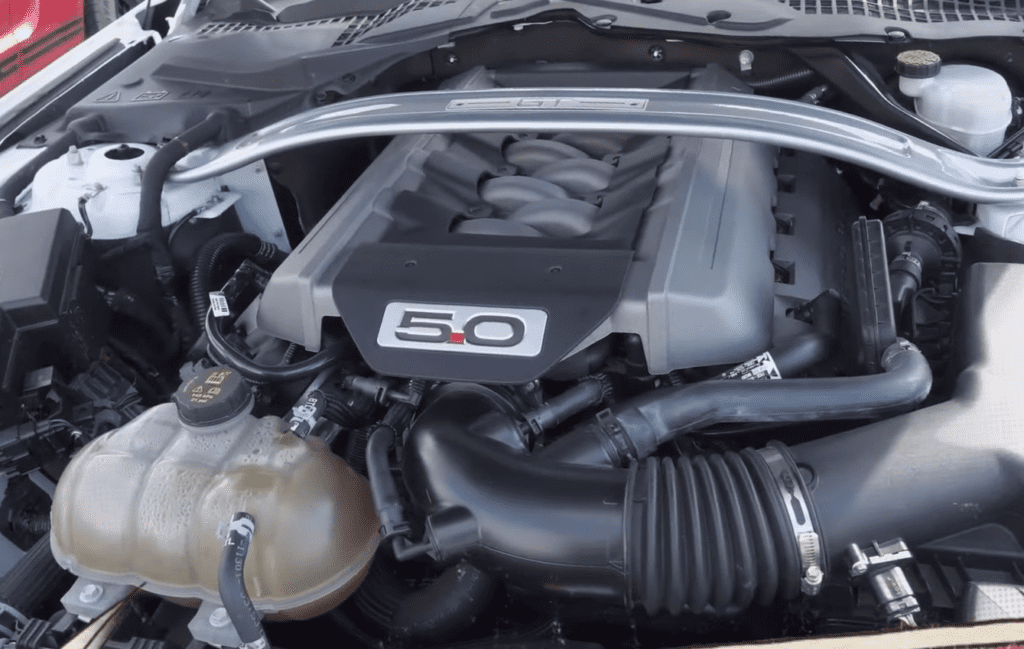

Fuel and Ignition Setup

From 2011–2017, the engine used sequential multi-port fuel injection. Starting in 2018, it adopted a dual system with both direct injection and port injection, improving efficiency and reducing carbon buildup.

The electronically controlled throttle body manages airflow, while coil-on-plug ignition ensures precise spark delivery. This combination supports both performance and reliability across different applications.

Performance Capabilities

Power Output and Torque Levels

The 5.0L Coyote V8 delivers different numbers depending on the model and year. Early versions from 2011–2017 in the Mustang GT reached up to 435 horsepower, while torque ranged between 380–420 lb-ft across applications. With the 2018 update, the Mustang variant climbed to 460 horsepower and pushed the redline higher, giving it stronger top-end performance.

| Model / Year | Horsepower | Torque (lb-ft) |

|---|---|---|

| Mustang GT (2011–2017) | Up to 435 | 380–400 |

| F-150 (2011–2017) | Lower HP, torque-focused | 400–420 |

| Mustang GT (2018+) | 460 | 420 |

Vehicle-Specific Calibration

Ford tuned the Coyote differently depending on the vehicle. The Mustang GT received stainless steel tubular headers and a performance-focused calibration for higher horsepower. In contrast, the F-150 used cast manifolds and a torque-oriented tune, making it better suited for towing and heavy-duty work. This split in design allowed the same engine architecture to serve both sports car and truck roles effectively.

Operation at Higher Engine Speeds

One of the defining traits of the Coyote is its ability to rev high for a naturally aspirated V8. The Gen 3 update in 2018 raised the redline to 7,500 RPM, giving drivers more usable power at the top end. Features like twin independent variable cam timing and an advanced intake system help the engine breathe efficiently across the rev range, balancing daily drivability with strong high-RPM performance.

Engineering Innovations

Adjustable Camshaft Control

The engine uses twin independent camshaft timing, which lets both intake and exhaust cams shift separately. This setup improves airflow, fuel use, and power across the rev range. By adjusting valve timing on the fly, it balances strong low-end torque with high-RPM performance.

Key points:

- Intake and exhaust cams adjust independently

- Stronger torque at low speeds

- Higher efficiency and power at peak RPM

Airflow and Exhaust System

The intake manifold includes variable runner control to manage airflow at different engine speeds. Mustang versions come with tubular stainless steel headers for better breathing, while F-150 models use cast manifolds built for towing strength and durability.

| Component | Mustang | F-150 |

|---|---|---|

| Intake Manifold | Plastic, variable runners | Plastic, variable runners |

| Exhaust | Tubular stainless headers | Cast iron manifolds |

Heat and Oil Management

Cooling jets spray oil on the pistons to reduce heat during heavy loads. The block design uses deep skirts and four-bolt main caps to keep the bottom end strong and stable. A forged steel crankshaft and powdered metal rods add durability, while hydraulic lash adjusters and roller finger followers keep the valvetrain reliable under stress.

Durability features:

- Piston cooling jets

- Forged steel crankshaft

- Four-bolt main bearing caps

- Hydraulic lash adjusters for smoother operation

Reliability and Longevity

Strength Across Different Versions

The first two versions of the 5.0L Coyote engine are known for lasting well beyond 200,000 miles when given routine care. Their forged crankshaft, strong connecting rods, and proven valve train design make them dependable for both daily use and high-rev driving. The third version delivers more power but introduces tighter tolerances and new materials that raise repair costs if problems occur.

Service and Upkeep Factors

Regular oil changes, cooling system checks, and fuel system cleaning help extend the life of the Coyote. Engines with both port and direct injection benefit from intake cleaning to prevent carbon buildup. Owners who keep up with these tasks usually avoid major issues and maintain strong performance over time.

- Oil and filter changes on schedule

- Cooling system inspection

- Intake cleaning for direct injection models

- Monitoring timing chain condition

Areas That Show Wear

Some early engines developed a light ticking sound. In many cases it caused no harm, but it could point to valve train wear if ignored. Direct injection models may show carbon buildup without regular cleaning. Plasma-coated cylinder walls in later versions improve efficiency but cannot be re-bored if damaged, making repairs more complex.

Notable concerns by generation:

| Generation | Common Issue | Repair Difficulty |

|---|---|---|

| Gen 1 & 2 | Occasional valve train tick | Low to moderate |

| Gen 3 | Carbon buildup, cylinder wall limits | Moderate to high |

Known Issues and Concerns

Ticking From the Valve System

Some early versions of the engine developed a light ticking sound in the valve system. In many cases, this noise caused no real harm, but it sometimes pointed to wear in the moving parts. Owners often noticed it most at idle or low speeds.

Key points:

- Often harmless but can indicate wear

- More common in first-generation models

- Usually heard at idle

Carbon Deposits in Direct Injection

With the addition of direct injection in later models, carbon buildup on intake valves became a concern. Without regular cleaning, these deposits can reduce airflow and affect performance. The dual fuel setup in newer engines helps reduce the issue but does not fully prevent it.

Maintenance tip:

- Routine cleaning of the intake system helps limit buildup

Limits of Plasma-Sprayed Cylinder Walls

The third generation uses plasma-sprayed liners instead of traditional cast iron. While lighter and efficient, these liners cannot be easily repaired if damaged. This means repairs can become more expensive compared to earlier designs.

Comparison Table:

| Feature | Cast Iron Liners (Gen 1 & 2) | Plasma Liners (Gen 3) |

|---|---|---|

| Durability | High | High but less forgiving |

| Repairability | Can be re-bored | Cannot be re-bored |

| Weight | Heavier | Lighter |

Average Fuel Efficiency

Fuel economy remains one of the weaker points of this engine. While it delivers strong power and quick throttle response, it does not match the efficiency of smaller turbocharged engines. Drivers who prioritize mileage may find this disappointing compared to Ford’s EcoBoost options.

Quick facts:

- Strong performance, but average efficiency

- Less competitive next to turbocharged V6 engines

Coyote Engine Verdict

The 5.0L Coyote stands out as one of Ford’s most balanced V8s, delivering both strength and modern engineering. Its forged crankshaft, durable valve train, and efficient cooling design give it the ability to handle high RPMs while still lasting well past 200,000 miles with proper care.

Strengths:

- High-revving power with strong torque

- Proven reliability in Gen 1 and Gen 2

- Naturally aspirated response and clean exhaust tone

- Widely used across Mustang, F-150, and performance models

Trade-offs:

- Some early models developed harmless but noticeable ticking

- Gen 3 offers more horsepower but comes with higher repair costs

- Direct injection can lead to carbon buildup without maintenance

- Plasma cylinder liners in Gen 3 cannot be easily repaired

| Generation | Fuel System | Power Output (Mustang) | Key Notes |

|---|---|---|---|

| Gen 1 (2011–2014) | Multiport Injection | Up to 420 hp | Reliable, simple design |

| Gen 2 (2015–2017) | Multiport Injection | Up to 435 hp | Strong longevity, easy to modify |

| Gen 3 (2018–present) | Dual Injection | Up to 460 hp | More power, higher maintenance |

Drivers who want long-term dependability often lean toward Gen 1 and Gen 2. Enthusiasts chasing maximum horsepower tend to prefer Gen 3, knowing it comes with added upkeep. The Coyote continues to earn respect for blending modern technology with the traditional feel of a naturally aspirated V8.